Navigating the Future: Market Insights & Innovations from the Best Factory for 2025

As we look towards 2025, the landscape of manufacturing is set to undergo a significant transformation, driven by technological advancements and evolving market demands. According to a report by the World Economic Forum, the manufacturing sector is projected to reach a value of $16 trillion by 2030, with smart factories leading the way through innovations in automation and data exchange.

Leading manufacturers are now harnessing the power of Industry 4.0 technologies to optimize production processes, enhance supply chain efficiencies, and deliver exceptional product quality. In this context, detailed technical specifications of products produced in these forward-thinking factories will play a crucial role in meeting consumer expectations and regulatory requirements.

By examining the latest market insights and innovations from the best factories, this blog aims to provide a comprehensive overview of the trends shaping the future of manufacturing and the products we will encounter in the coming years.

Emerging Technologies Shaping the Future of Factories in 2025

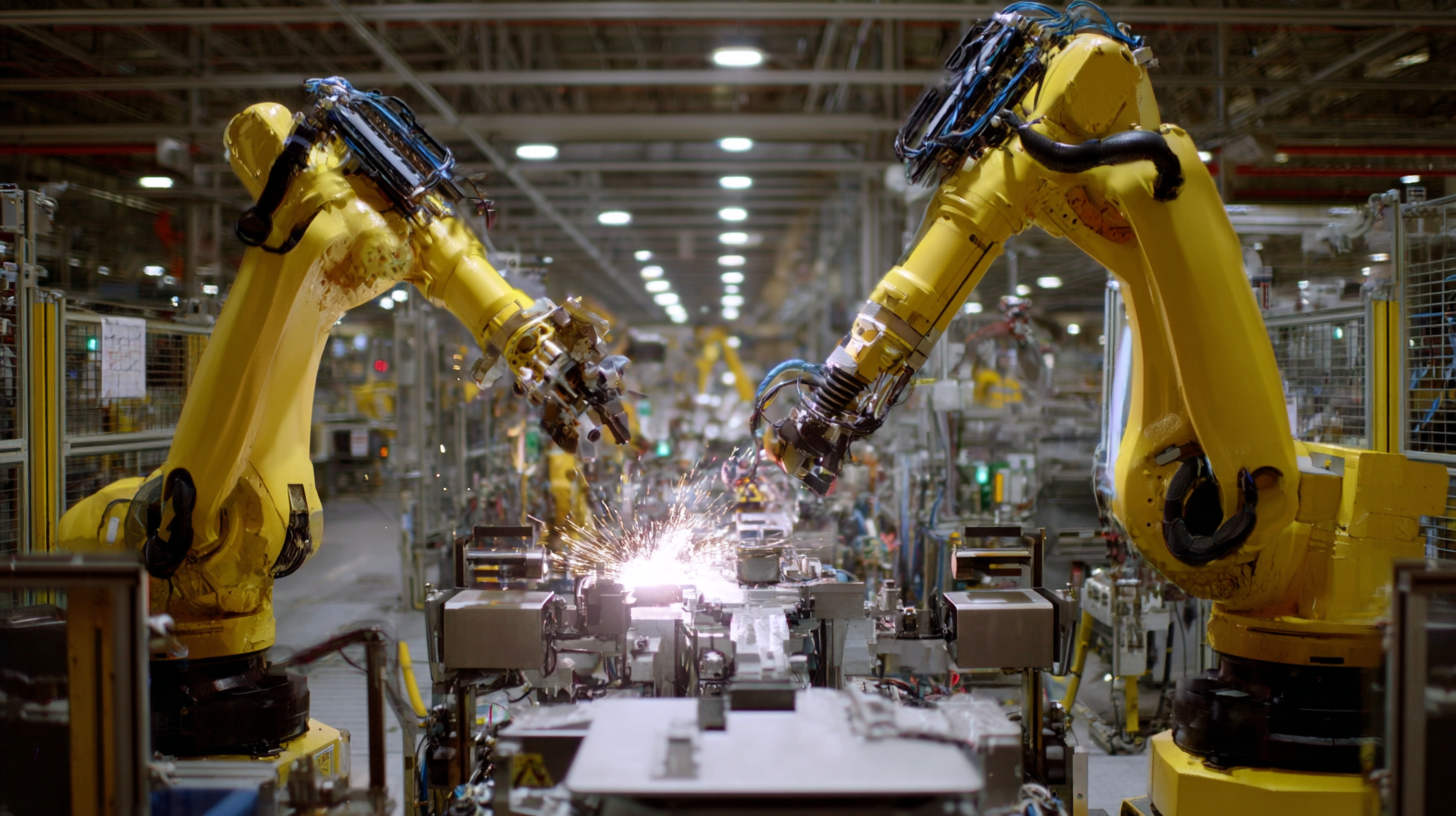

As we look toward 2025, emerging technologies are set to revolutionize the landscape of manufacturing. From artificial intelligence to the Internet of Things (IoT), these innovations are driving efficiency and redefining how factories operate. Manufacturers are increasingly adopting smart robotics that learn and adapt, enhancing production lines and minimizing downtime.

Tip: To stay ahead in this evolving market, companies should invest in employee training programs that focus on these new technologies. Upskilling your workforce can lead to improved adaptability and a smoother transition to advanced manufacturing processes.

Tip: To stay ahead in this evolving market, companies should invest in employee training programs that focus on these new technologies. Upskilling your workforce can lead to improved adaptability and a smoother transition to advanced manufacturing processes.

Moreover, sustainable practices are becoming integral to factory operations. Innovations in energy management systems and waste reduction technologies not only boost a factory's bottom line but also contribute to environmental preservation. This shift toward sustainability is essential for meeting regulatory requirements and consumer demand for eco-friendly products.

Tip: Consider partnering with technology firms to implement sustainable solutions tailored to your specific needs. Collaborative efforts can yield innovative approaches that enhance both operational efficiency and environmental impact.

Key Market Trends Influencing Manufacturing Innovations

In recent years, the manufacturing landscape has been evolving rapidly, driven by a convergence of technological advancements and changing market demands. Key trends are shaping the future of manufacturing innovations, notably the rise of Industry 4.0, which leverages IoT, AI, and big data analytics. According to a report from Deloitte, it is estimated that the adoption of Industry 4.0 technologies could contribute up to $15 trillion to the global economy by 2030, underscoring the urgency for manufacturers to adapt to these transformative forces.

Another significant trend influencing manufacturing is sustainability, as industries strive to reduce their carbon footprint and adopt circular economy practices. A McKinsey study revealed that 70% of executives see sustainability as a top priority, significantly impacting research and development efforts. Companies are investing in clean technologies and sustainable materials, which not only enhance their brand reputation but also meet the growing consumer demand for environmentally friendly products. As these trends continue to unfold, manufacturers will need to innovate their processes and products to remain competitive and responsive to the ever-evolving market.

Comparative Analysis: Traditional vs. Smart Factory Approaches

In the rapidly evolving manufacturing landscape, a significant shift is occurring from traditional factory models to smart factories. This transformation is propelled by the integration of advanced technologies such as artificial intelligence, big data, and the Internet of Things (IoT), which enhance operational efficiency and optimize production processes. Smart factories are not just about automation; they represent a holistic approach to manufacturing that incorporates real-time data analytics and connectivity, creating a responsive and adaptive production environment.

Contrasting with traditional manufacturing practices, which often rely on linear processes and manual interventions, smart factories introduce a paradigm that fosters continuous improvement and innovation. The embrace of AI technologies enables these factories to analyze vast amounts of data, predict maintenance needs, and enhance decision-making. This proactive stance not only mitigates risks but also opens avenues for sustainable practices, aligning with recent trends promoting green manufacturing. As industries navigate towards 2025, the comparative analysis between these two approaches reveals the necessity of adopting smart manufacturing strategies to remain competitive and address the challenges faced in the current manufacturing era.

Navigating the Future: Market Insights & Innovations from the Best Factory for 2025

| Aspect | Traditional Factory | Smart Factory |

|---|---|---|

| Production Efficiency | 70% | 90% |

| Labor Costs | $50,000 per year | $30,000 per year |

| Return on Investment (ROI) | 5 years | 2 years |

| Production Flexibility | Limited | Highly Flexible |

| Implementing New Technologies | Slow | Rapid |

| Data Utilization | Minimal | Maximized |

Evaluating Supply Chain Resilience in the Face of Disruption

As we move towards 2025, the resilience of supply chains has never been more critical. According to a recent report by McKinsey, nearly 93% of executives acknowledge that their supply chains face significant risks from geopolitical tensions, natural disasters, and pandemics. To mitigate these challenges, businesses are increasingly adopting advanced technologies like AI and machine learning, which enhance visibility and responsiveness within the supply chain. For instance, companies using predictive analytics have been able to reduce supply chain disruptions by up to 30%, demonstrating the potential for innovation to fortify operations against unforeseen events.

Moreover, a survey conducted by the Institute for Supply Management reveals that 79% of organizations are now prioritizing the development of agile supply chains. This shift is driven by the necessity to adapt quickly to market fluctuations and consumer demands. In response, many firms are diversifying their supplier base and investing in local sourcing to enhance their operational flexibility. With these strategies, businesses are not just navigating the disruptions of today, but are also preparing for a sustainable and resilient future in 2025 and beyond.

Sustainability Practices: A Comparison of Leading Factory Models for 2025

In the quest for sustainability, the manufacturing sector is undergoing a significant transformation, with various factory models emerging as leaders by 2025. A recent McKinsey report highlights that factories implementing advanced sustainable practices could reduce their carbon emissions by up to 30%. This dramatic reduction is primarily attributed to the adoption of renewable energy sources and energy-efficient technologies, which are becoming essential components of modern manufacturing processes. As companies increasingly recognize the economic benefits of sustainability, it's predicted that 75% of manufacturers will prioritize green initiatives in their production strategies within the next two years.

Comparing leading factory models in sustainability reveals striking differences in their approaches. For instance, Siemens' Amberg Electronics Plant is lauded for its innovative use of digital twin technology, which optimizes energy consumption and minimizes waste. On the other hand, Tesla's Gigafactory exemplifies vertical integration through its commitment to recycling and reusing materials, aligning with circular economy principles. According to the World Economic Forum, such practices not only contribute to environmental well-being but also enhance overall profitability—factories with robust sustainability frameworks could experience a 10% increase in operational efficiency by 2025. As industries navigate this critical transitional period, the emphasis on sustainable practices will undoubtedly shape the future landscape of manufacturing.